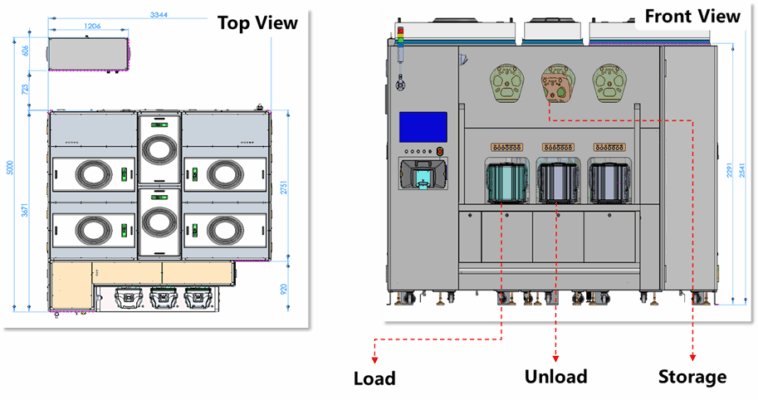

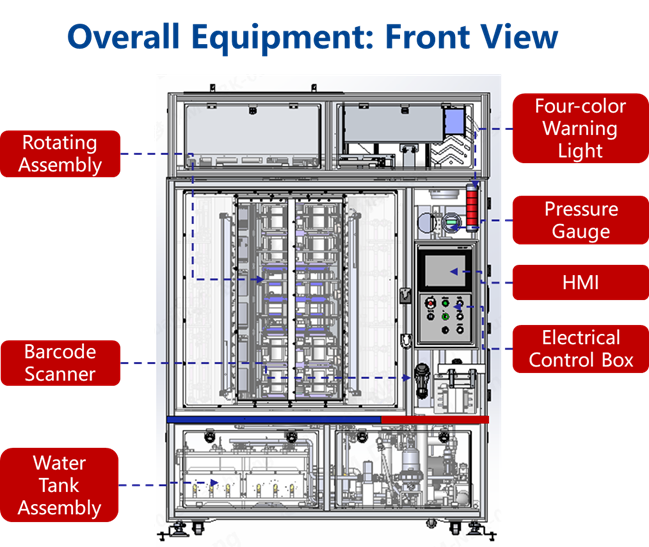

Model: Xtrim-FC-A300

- The Xtrim-FC-A300 is a fully automated FOUP/FOSB cleaning system designed for high-volume semiconductor production environments. Engineered for superior cleanliness, fast throughput, and safety compliance, it ensures contamination-free wafer transport throughout the fab.