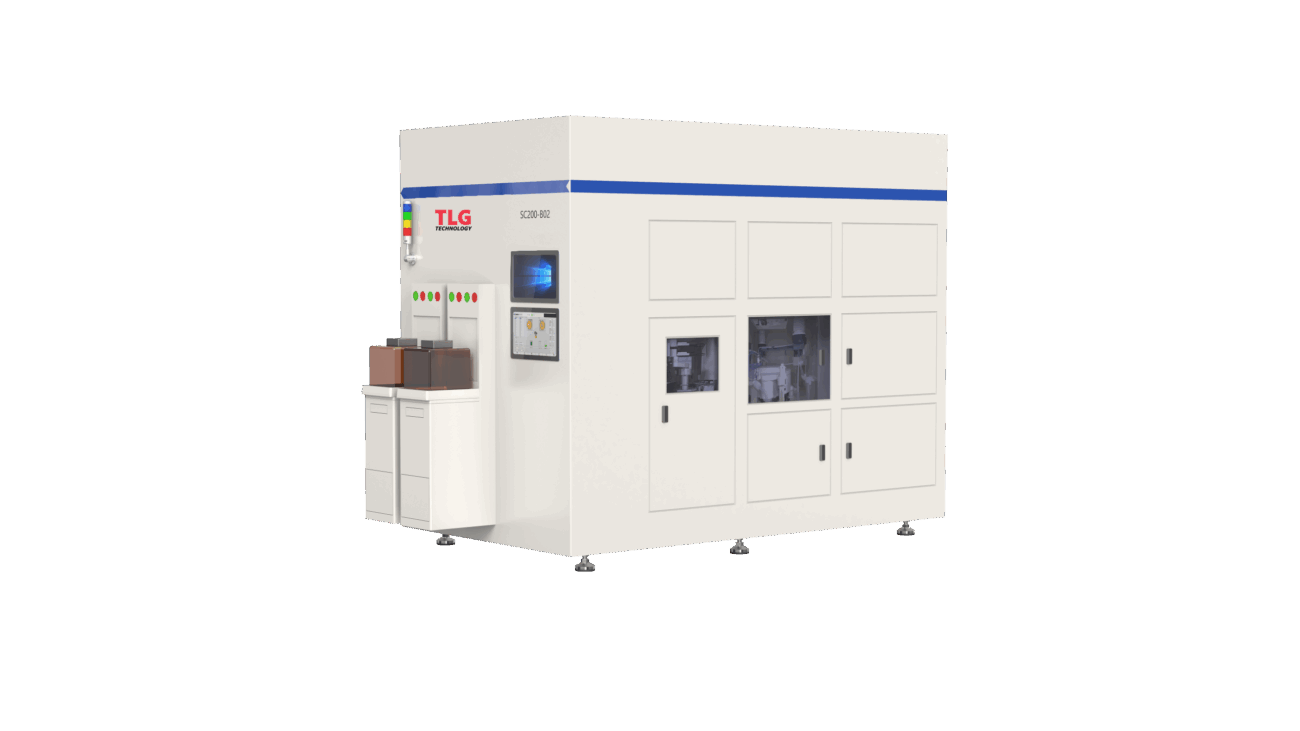

Model: SC200-B02

Precision Cleaning • Compact Design • Chemical Efficiency

- The SC200-B02 delivers exceptional performance for single-wafer cleaning and surface preparation. Designed for 6″ and 8″ wafer applications, this system meets the critical demands of R&D centers, pilot lines, and volume fabs requiring high process control, low particle performance, and superior reliability.