Automated Mapping Systems

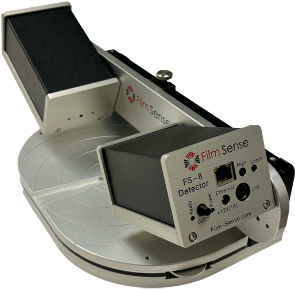

The FS-RT300 combines an FS-8 Multi-Wavelength Ellipsometer with a compact automated mapping stage to provide fast, accurate, and reliable film thickness uniformity measurements across a wafer.

The FS-RT300 combines an FS-8 Multi-Wavelength Ellipsometer with a compact automated mapping stage to provide fast, accurate, and reliable film thickness uniformity measurements across a wafer.

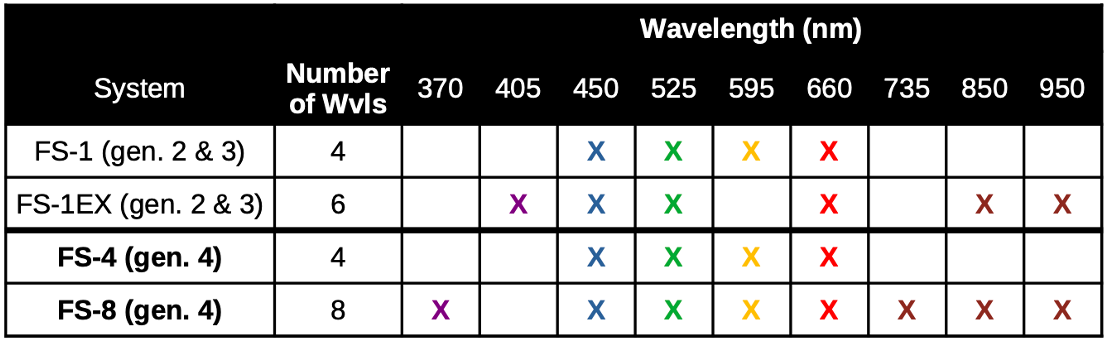

The 4th generation Film Sense Multi-Wavelength Ellipsometer systems are now available, with more wavelengths and wider spectral range!

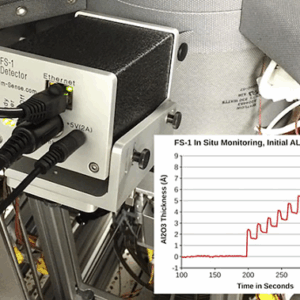

Film Sense Multi-Wavelength Ellipsometers are ideal for in situ realtime monitoring and control of thin film deposition and etching processes.

Key Features and Benefits of all Film Sense Multi-Wavelength Ellipsometers

| Features | Benefits |

|---|---|

| Multiple LED sources (either 4 or 8, with wavelengths ranging from 370 – 950 nm, depending on the system) | Long lifetimes (>50,000 hours), with no costly lamp changes, time consuming alignments or PM procedures |

| No moving parts in the ellipsometric detector* | Fast measurement times (ellipsometric data in 1.7 ms, with the new Fast Mode feature) and long term reliability |

| Excellent thickness precision, better than 0.0004 nm for many samples (for a 1 second acquisition), even for sub-monolayer film thicknesses | Measurement precision that is only possible with an ellipsometer |

| Integrated computer for instrument control and data analysis, with a web browser interface accessible from any modern computer, laptop, or tablet | No complicated software setup and maintenance |

| Completely self-contained system | No external electronics box or fiber connections |

* US Patent #9,354,118

The 4th generation Film Sense Multi-Wavelength Ellipsometer systems are now available! The primary improvements in this generation are the additional wavelengths and spectral range for the FS-8 model, which further enhance the measurement capabilities over a wide range of thin film applications. The new systems offer the same benefits of the patented* Film Sense ellipsometer technology (long life LED light sources, fast and reliable no moving parts detector, compact design, and web browser software interface), while maintaining ease of use and affordability.

*US Patent #9,354,118

These products combine an FS Multi-Wavelength Ellipsometer with compact mapping stages to provide fast, accurate, and reliable film thickness uniformity measurements across a wafer.

The FS Ellipsometer Multi-Wavelength Ellipsometer is ideal for Atomic Layer Deposition (ALD) applications